Wide range of services

Our experience takes you further for the future!

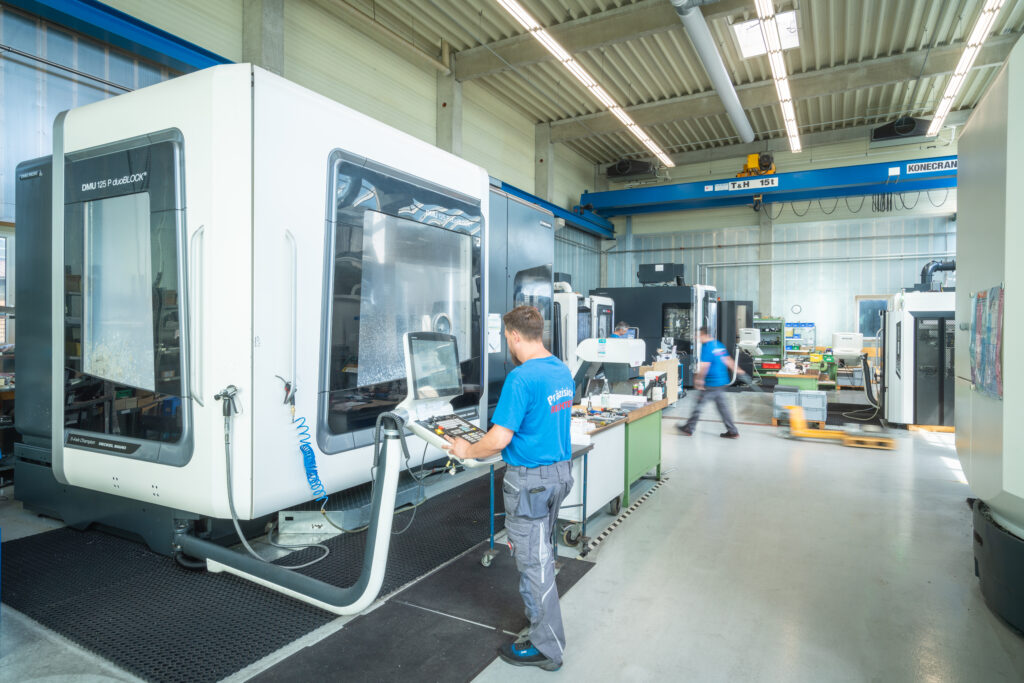

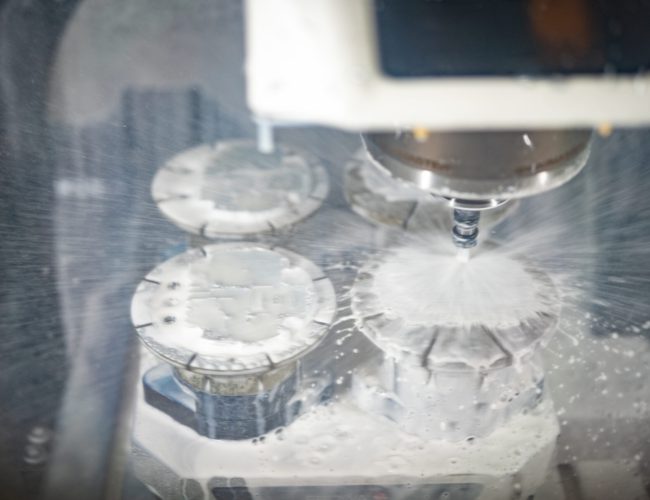

CNC Machining

With our 5-axis machining capabilities, we produce complex components and prototypes in a single setup – saving time and increasing dimensional accuracy. For brittle materials such as ceramics and carbides, we use advanced ultrasonic technology. Thanks to pallet automation systems, our milling processes are perfectly suited not only for individual parts and prototypes, but also for small and medium series production. We also specialize in graphite machining – particularly for bipolar plates used in hydrogen production.

- Milling volume up to 1.5 m³ (1,250 × 1,000 × 1,000 mm)

- Workpiece weight up to 3 tons

- Precision up to ±0.005 mm

- All materials – from prototypes to series production

Machining Technologies

- 3D & Multi-Axis Machining (5-Axis Simultaneous)

Precision milling of complex geometries with maximum flexibility. - High-Speed Cutting (HSC)

High-speed machining with linear drives for ultra-fine surface finishes. - Hard Machining up to 70 HRC

Direct machining of hardened materials – no intermediate steps required. - Graphite Machining

Special milling strategies for erosion-resistant materials. - Ultrasonic Machining

Ultrasonically assisted grinding technology to reduce cutting forces and tool wear-ideal for brittle materials. - Vacuum Clamping Technology

Clamping systems for distortion-free and delicate machining.

Materials & Alloys

- High-Performance Metals

Titanium, Inconel, Hastelloy, Kovar, Invar, Ampco - Non-Metals

Macor, glass ceramics, technical ceramics, glass - Hard and Specialty Materials

Carbide, cermets, nitrides, tungsten, tungsten copper - Standard Materials

Steel, stainless steel, non-ferrous metals, plastics

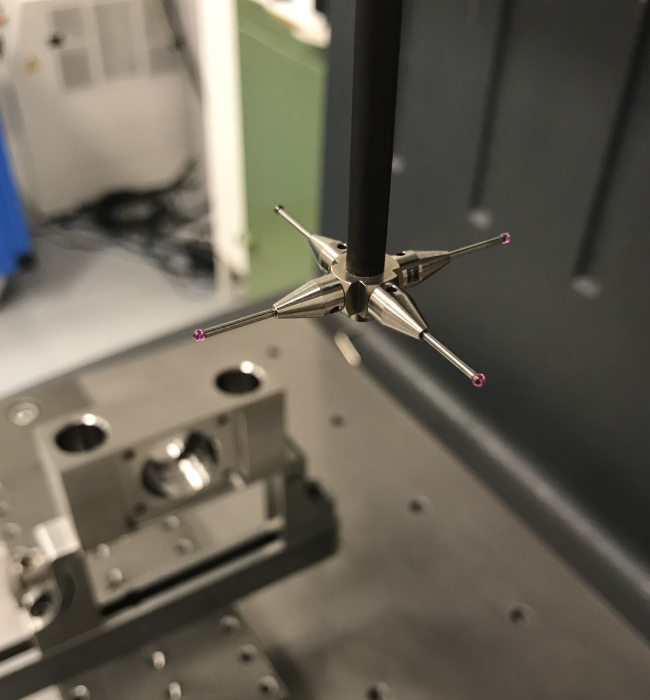

Metrology

Our optical and tactile measurement technologies enable precise inspection and documentation of manufactured components. Using ZEISS measuring systems – including the ACCURA coordinate measuring machine – we capture dimensions, shapes, and positions, even for large-scale workpieces. By combining different measurement methods, we ensure comprehensive quality assurance. Our processes are certified according to DIN EN 9100:2018 for aerospace applications.

- Measuring range up to 3 meters

- Workpiece weight up to 5 tons

- Accuracy of 6 μm over a 3-meter measuring length

- Measuring depth up to 800 mm

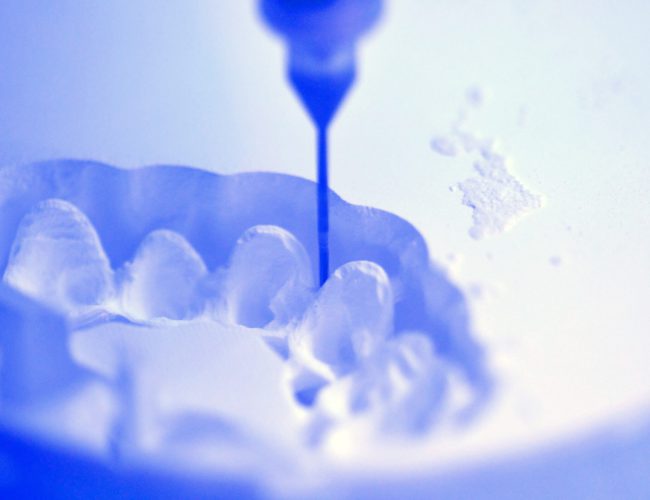

3D Printing

Our platform offers a comprehensive selection of technologies and materials for high-precision 3D printing solutions. As a Jellypipe Solution Partner, we ensure top-quality results for components, assemblies, prototypes, and more. From simple to complex projects – we make it fast and easy. From inquiry to order in just 30 seconds: upload your file, configure your part, and place your order.

- Variety: Over 100 materials and 14 technologies

- Expert Support: Personalized consulting for your project

- Precision: Industrial-grade print quality and post-processing by our team

- Efficiency: Fast and straightforward order processing

System Supplier

We offer manufacturing services in close collaboration with long-standing partner companies. Our range of services includes waterjet and laser cutting, wire and sinker EDM, as well as complete sheet metal processing and surface treatments. All processes are designed for high dimensional accuracy and repeatability.

- Waterjet cutting: With and without abrasive additive, for different materials

- Laser Cutting: Processing of thin and thick sheet metal in variable thicknesses

- EDM: Wire and sinker electrical discharge machining with up to 500 mm workpiece height

- Surface Treatment: Hardening, coating, and other common finishing processes

Assembly

Comprehensive solutions for component and assembly integration. High manufacturing standards, modern equipment, and experienced specialists ensure reliable results and on-time execution. Upon request, we also integrate standard and purchased parts into the assembly process. Quality is guaranteed through documented inspection reports in accordance with customer-specific requirements.

- Completed assemblies

- Integration of standard and purchased parts

- Qualified professionals

- Documentation available upon request

Our Machinery Fleet

From small to large, from specialized components to full-scale series production – our machinery fleet features state-of-the-art DMG milling machines for the precise machining of complex geometries. For quality assurance, we rely on ZEISS measuring systems to accurately verify and document dimensional accuracy and tolerances.